Aktuelle Themen

bei uns in der Schleiftechnik

Die ökonomisch und ökologisch nachhaltige sowie effiziente Herstellung von Produkten wird angesichts des zunehmenden globalen Wettbewerbs

zur Voraussetzung für produzierende Unternehmen, die ihre Wettbewerbsposition langfristig sichern wollen. Die isolierte Verbesserung der

einzelnen Fertigungsprozesse führt dabei nicht immer zwangsläufig zum idealen Kosten- bzw. Zeitoptimum, da die Abhängigkeiten hinsichtlich

der Wirtschaftlichkeit, Ökologie und Qualität zwischen den einzelnen Fertigungsprozessen unberücksichtigt bleiben. Die ganzheitliche Optimierung

der gesamten Prozesskette ist für ein produzierendes Unternehmen daher entscheidend, um nachhaltig wettbewerbsfähig zu bleiben. Ein wesentliches

Potenzial liegt hierbei in der datenbasierten Betrachtung der Abhängigkeiten von Fertigungsprozessen innerhalb einer prozessübergreifenden

Fertigungsprozessfolge. Um diese Abhängigkeiten datenbasiert bewerten und Optimierungen ableiten zu können, müssen neue Methoden konzipiert

und kontinuierlich weiterentwickelt werden.

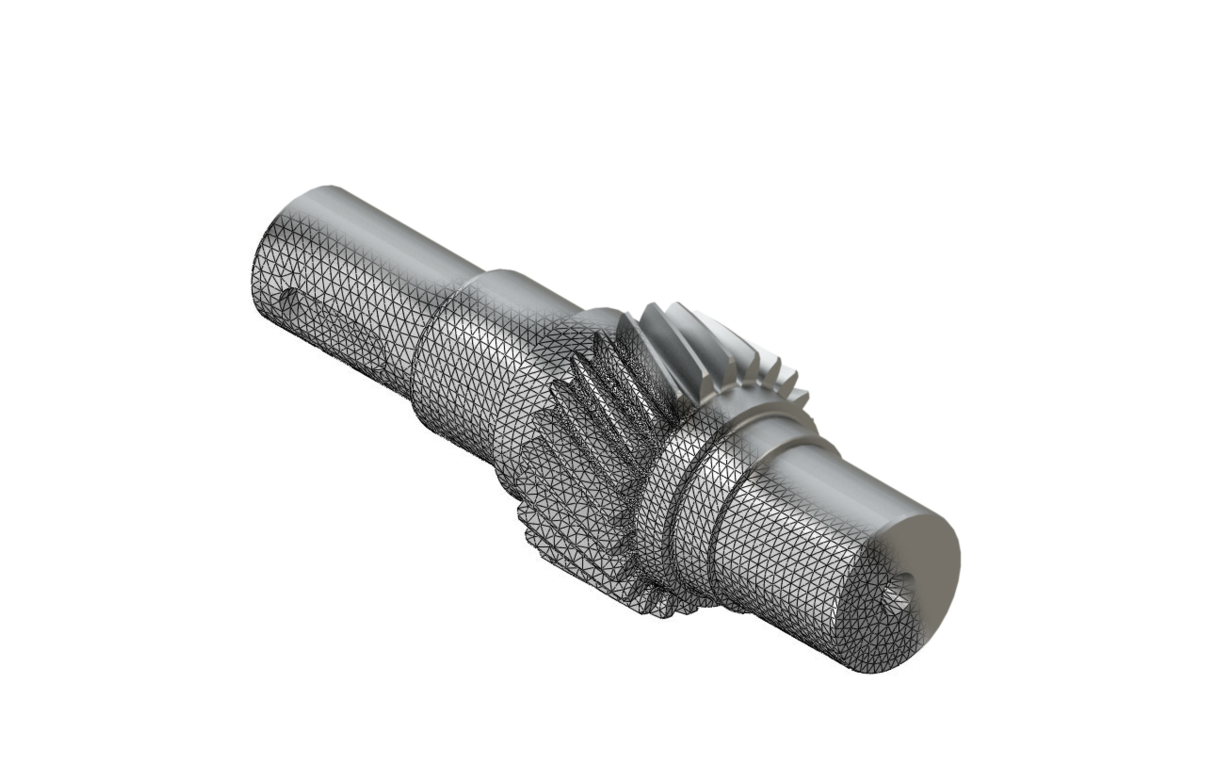

Im Inkubator Technologiekette des WZL wird an einer standardisierten Lösung gearbeitet, um prozessübergreifende Fertigungsprozessfolgen digital

abzubilden und zu optimieren. Dabei umfasst die Optimierung sowohl eine ökologische Bewertung als auch eine Bewertung der ökonomischen Effizienz.

Grundlage für diese Entwicklungen ist eine Fertigungsprozessfolge für die Herstellung von Ritzelwellen für die Getriebe von Elektroautos.

Der digitalisierte Prozessablauf besteht dabei aus den Verfahren Drehen, Wälzfräsen, Einsatzhärten, Rundschleifen und Verzahnungsschleifen,

wobei über 250 Bauteile mit unterschiedlichen Prozessauslegungen gefertigt wurden. Innerhalb der Untersuchungen für das Rundschleifen konnten

hierbei bereits Einflüsse des Drehens auf den Schleifprozess festgestellt werden, die eine Notwendigkeit der übergreifenden Optimierung

signalisieren.

More informations:

Eike Reuter, M. Sc

+49 (0) 241 80 25388

E.Reuter@wzl.rwth-aachen.de

Interesse aneiner Mitgliedschaft?

. . . . . . . . . . . . . .

zurück zum Seitenanfang

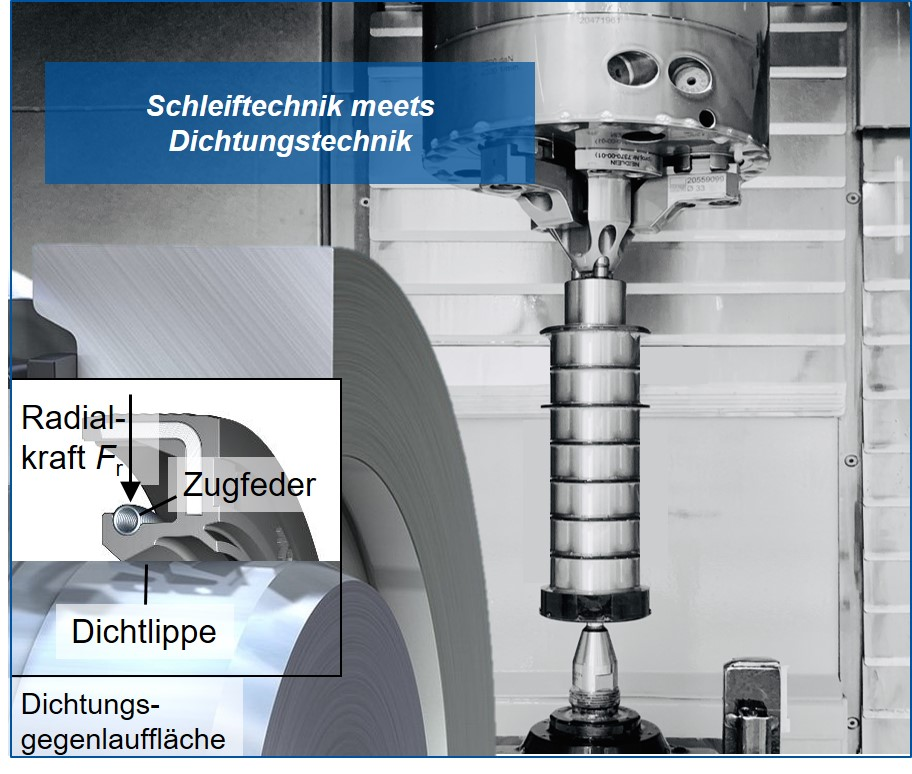

Höhere Temperaturen und höhere Gleitgeschwindigkeiten in elektrischen Antriebssträngen stellen die Dichtungstechnik vor große Herausforderungen.

Damit der Einsatz ressourcenschonender Systeme nicht an der mangelnden Abdichtfähigkeit scheitert, müssen neben den Dichtelementen auch die

tribologischen Eigenschaften der Dichtungsgegenlaufflächen durch Schleifen optimiert werden. Geschliffene Dichtungsgegenlaufflächen bestehen

aus einer Vielzahl an Einzelstrukturen, die aufgrund ihrer doppelt konvergenten Form bei Wellenrotation zum Aufbau eines für die Dichtlippe

verschleißschützenden Schmierfilms führen. Unter ungünstigen Bedingungen kann beim Einstechschleifen die Orientierung der einzelnen

Schleifstrukturen jedoch von der Umfangsrichtung abweichen. Dieser sogenannte Mikrodrall ist aufgrund der hohen Förderwirkung bei hohen

Drehzahlen besonders schädlich für ein Dichtsystem und muss daher beim Schleifen durch eine wissensbasierte Prozessauslegung vermieden werden.

Daher erforscht das Werkzeugmaschinenlabor WZL der RWTH Aachen derzeit in einem Kooperationsprojekt mit den Experten für Dichtungstechnik und

Mikrodrallanalyse des Instituts für Maschinenelemente IMA der Universität Stuttgart die Entstehungsmechanismen von Mikrodrall beim Schleifen.

More informations:

Jannik Röttger, M. Sc

+49 (0) 241 80 24959

J.Roettger@wzl.rwth-aachen.de

Interesse aneiner Mitgliedschaft?

. . . . . . . . . . . . . .

zurück zum Seitenanfang

Die Aachener Schleiftechnik – wir sind begeisterte Experten für zukunftsweisende Schleifprozesstechnologien. Schwerpunkte unserer Forschung am

WZL der RWTH Aachen sind neue und innovative Werkstoffe, Finishing-, Spitzenlos- und Werkzeugschleifprozesse sowie Technologien zur Erzeugung

feiner und funktionale Oberflächen, die datengetriebene Modellierung von Schleifprozessen und modellbasiertes Schleifprozessdesign.

Verfolgen Sie gerne unser neues LinkedIn-Profil

auf dem wir Ihnen die Produktionstechnologie von morgen aus unserer Sicht präsentieren werden.

More informations:

Peter Breuer, M. Sc

+49 (0) 241 80 27367

P.Breuer@wzl.rwth-aachen.de

Interesse aneiner Mitgliedschaft?

. . . . . . . . . . . . . .

zurück zum Seitenanfang

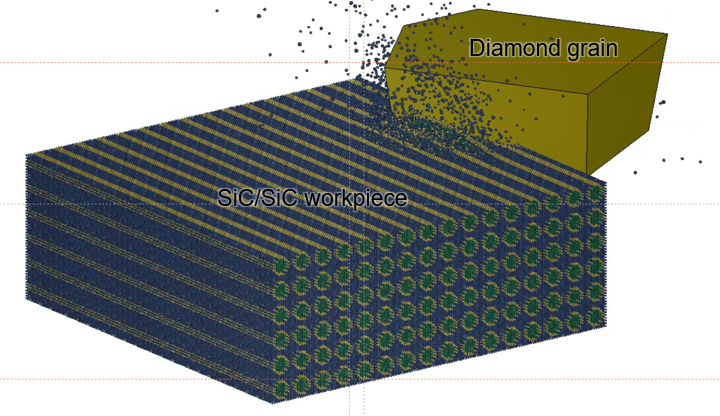

Two-phase, brittle-hard materials are widely used not only in the tool industry, but increasingly also in the aerospace industry.

Due to the two-phase nature, the materials have unique material properties adapted to the respective application. However, these

material properties lead to a more complex machining behavior. In order to analyze the material removal behavior of the grinding

process and to be able to design the grinding process, the analogy process single grain scratching is used. The Smoothed Particle

Hydrodynamics (SPH) method enables the numerical simulation on mesoscale with moderate computational time. In research projects at

WZL, the single grain scratching of WC-Co cemented carbides and of non-oxide ceramics (SiC/SiC) have been developed.

The picture shows the engagement of a diamond grain into a non-oxide ceramics workpiece.

More informations:

Alexander Dehmer M. Sc

+49 (0) 241 80 24981

A.Dehmer@wzl.rwth-aachen.de

Interesse aneiner Mitgliedschaft?

. . . . . . . . . . . . . .

zurück zum Seitenanfang

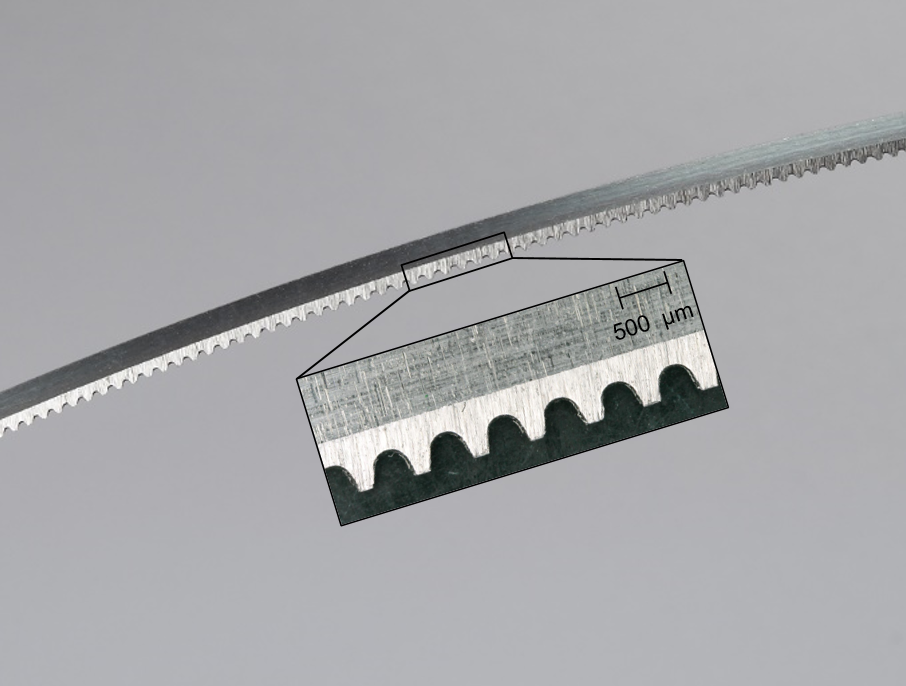

The production of bandknives for foam cutting systems requires a profound understanding of the operational behaviour of the bandknives.

The operational behaviour essentially depends on the macro- and microgeometry of the cutting edge and is a function of the selected

grinding parameters. Together with the company Albrecht Bäumer GmbH & Co. KG, the Group of Grinding Technology of the WZL is

researching the knowledge-based design of grinding processes for the production of functionally optimized bandknives within a Central

Innovation Programme for SMEs (ZIM).

More informations:

Eike Reuter, M. Sc

+49 (0) 241 80 25388

E.Reuter@wzl.rwth-aachen.de

Interesse aneiner Mitgliedschaft?

. . . . . . . . . . . . . .

zurück zum Seitenanfang

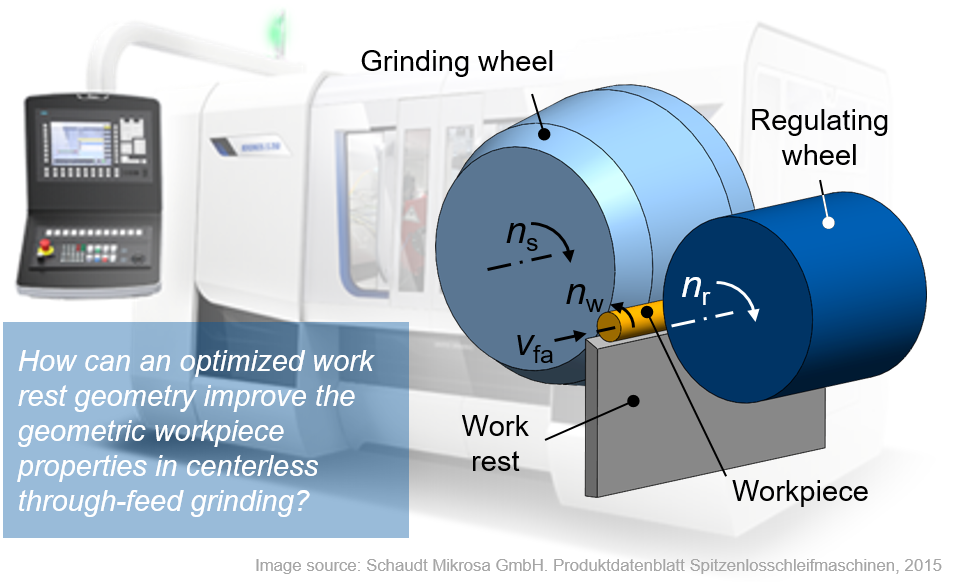

Centerless through-feed grinding is a highly productive manufacturing process for the fine machining of large numbers of mainly

cylindrical surfaces. With the work rest geometries commonly used in industry today, it is impossible to ensure complete support of

the workpiece during the entire grinding process, which can lead to form errors on the ground part. At the Laboratory for Machine

Tools and Production Engineering WZL of RWTH Aachen University, research is carried out to improve the support of the workpiece

through optimized work rail geometries. The project aims to reduce workpiece form errors and workpiece grinding wheel wear.

More informations:

Peter Breuer, M. Sc

+49 (0) 241 80 27367

P.Breuer@wzl.rwth-aachen.de

Interesse aneiner Mitgliedschaft?

. . . . . . . . . . . . . .

zurück zum Seitenanfang

In the grinding industry, fine filtration is often used to keep the degree of contamination of the cooling lubricant as low as possible. But how does this

fine filtration influence the lubricant and its properties? The research conducted at WZL focuses on two aspects of the filtration of cooling lubricants.

First, the effectiveness of filtration depends on the structure and density of the filtration fleece. Secondly, a chip layer forms on the fleece during

grinding, which also influences the filtration system. To investigate these two aspects, a test rig was set up at WZL. The properties of the cooling

lubricant are determined and compared to its original properties. Based on this knowledge, recommendations for cooling strategies in grinding technology

are derived.

More informations:

David Braun, M. Sc

+49 (0) 241 80 20392

D.Braun@wzl.rwth-aachen.de

Mass finishing is a versatile manufacturing technology, which is often the most economical choice. However, the process design is

still carried out according to the trial-and-error principle. At WZL we investigate the contact between abrasive media and workpiece,

in order to understand how the required process result can be achieved. Therefore, we use the discrete element method (DEM) for numerical

modeling of the kinematics of the abrasive media. This gives an insight into how the kinetic energy of the abrasive media is

transferred to the workpiece.

More informations:

Marius Ohlert M. Sc

+49 (0) 241 80 27429

M.Ohlert@wzl.rwth-aachen.de

Combining a high hardness and ductility, WC-Co cemented carbides are a widely used group of cutting tool materials. At WZL,

the Smoothed Particle Hydrodynamics (SPH) simulation of cemented carbide grinding processes is researched. The analogous single

grain scribing simulation contributes to a reduction of the preliminary tests necessary for the grinding process design and thus

to the economic efficiency and sustainability of the grinding process. Furthermore, the results can be transferred to a hybrid

AI that combines the methods of knowledge-based process design with the possibilities of artificial intelligence.

More informations:

Peter Breuer, M. Sc

+49 (0) 241 80 27367

P.Breuer@wzl.rwth-aachen.de

Power train components with improved surface qualities promise increased efficiency of the power trains and thus lower greenhouse gas emissions.

To meet the required surface qualities, elastic bonded grinding wheels offer the potential of surface finishing on the edge of polishing.

For a successful application their special characteristics require a new understanding of the grinding process. Through systematic investigations

of the operational behavior, this process understanding is being developed and implemented in close proximity to industry at WZL.

More informations:

Eike Reuter, M. Sc

+49 (0) 241 80 25388

E.Reuter@wzl.rwth-aachen.de

Der Arbeitskreis Werkzeugtechnik heißt die Firma Agathon als neustes Mitglied herzlich willkommen!

Wir freuen uns, mit AGATHON in Zukunft an spannenden Themen der Werkzeugtechnik arbeiten zu dürfen. Die Firma Agathon gilt als einer der führenden Hersteller von Werkzeugschleifmaschinen

für Wendeschneidplatten und bietet als Hybridverfahren die lasertechnische Vorbearbeitung von hochharten Werkstoffen an. Zudem fertigt die Firma Agathon Normalien.

More informations:

Alexander Dehmer M. Sc

+49 (0) 241 80 24981

A.Dehmer@wzl.rwth-aachen.de

zurück zum Seitenanfang

Innovative wear-resistant coatings are increasingly demanded for extreme corrosive conditions in order to enhance the life of wear parts. Due to the

strong bonding to the substrate, laser cladding is a potential coating technology for welding of anti-corrosive metal matrix composites, such as chromium carbide

with nickel as a binder. Since laser cladded coatings tend to form microcracks due to the large temperature gradient, the post-processing of these coatings is highly

relevant to prevent failure during its use-phase. Hence, the #WZL and the #IOT conduct cooperative research in order to enable knowledge-based process design for laser

cladding and grinding of chromium carbide nickel-based wear coatings.

More informations:

Ulrich Müller M. Sc

+49 (0) 241 80 28188

U.Mueller@wzl.rwth-aachen.de

At the end of last year, we received early Christmas presents from the company Rösler Oberflächentechnik GmbH. One is the R150 DL-2 vibratory finishing system,

which is highly relevant for machining components with a complex geometry, such as a blisk. The other is the RSF700 Surf-Finisher, which is characterized by component

handling with an industrial robot. This results in targeted local machining of the component and a high level of automation through automated loading and unloading.

This expansion of our plant technology will enable us to cover a wide range of applications in the field of post-processing in the future, e.g. aerospace components.

Together with the DAP, we are increasingly addressing the post-processing of additively manufactured components.

More informations:

Marius Ohlert M. Sc

+49 (0) 241 80 27429

M.Ohlert@wzl.rwth-aachen.de

For different applications, tools with different cemented carbide specifications are used. Research has shown that due to the varying material properties,

the grinding behavior changes for different cemented carbide specifications. The group of grinding technology at WZL has investigated the

cause-effect-relationships between the cemented carbide specification, the machining behavior during grinding and the surface integrity in several

publicly funded projects and the Research Circle Tooling Technology AKWT. This enabled a knowledge-based grinding process.

For further investigations of the external zone of the ground cemented carbides, transmission electron micrographs have been obtained

by the GFE of RWTH Aachen University. These micrographs made it possible to analyze the different effects of the machining on the two

phases of the cemented carbide tools.

More informations:

Alexander Dehmer M. Sc

+49 (0) 241 80 24981

A.Dehmer@wzl.rwth-aachen.de

Fiber-reinforced non-oxide ceramics (SiC/SiC) are innovative materials with high growth potential in the aerospace industry due to their

advantageous physical properties. Due to the manufacturing-related inaccuracies in shape, the SiC/SiC components often have to be ground

to their final dimensions. According to the state of art, the grinding process is characterised by low productivity due to the high

demand on surface and subsurface quality. This results in long grinding process times and thus has a negative effect on the profitability

of the grinding process. This problem is solved at the WZL through a systematic identification and analysis of multi-stage grinding

process strategies with regard to the achievable surface quality and the productivity when grinding fiber-reinforced non-oxide

ceramics (SiC/SiC). This approach enables manufacturers of SiC/SiC components to increase their productivity.

More informations:

Sebastian Prinz, M. Sc

+49 (0) 241 80 20393

S.Prinz@wzl.rwth-aachen.de

In the grinding industry, fine filtration is often used to keep the degree of contamination of the cooling lubricant as low as possible.

But how does this fine filtration influence the lubricant and its properties? In order to investigate this problem, a test rig at WZL

was set up which makes it possible to expose the cooling lubricant to high shear forces. The properties of the cooling lubricant are

determined and compared to its original properties. Based on this knowledge, recommendations for cooling strategies in grinding technology

are derived.

More informations:

David Braun, M. Sc

+49 (0) 241 80 20392

D.Braun@wzl.rwth-aachen.de

The Research Circle Grinding Technology (AKS) of the WZL is bringing together experts in the field of grinding technology and the expertise of companies

from the fields of grain and grinding wheel production, grinding machine production, cooling lubricant production, the automotive supplier industry

and the energy and aviation industries. This year's online annual meeting focused on new trends such as the grinding of high-temperature resistant

materials or assistance systems for process monitoring with machine learning. Many thanks to all members for their participation and the great support

during the project realisation.

More informations:

Jannik Röttger, M. Sc

+49 (0) 241 80 24959

J.Roettger@wzl.rwth-aachen.de

Integration of measuring systems in grinding machines for process monitoring is generally associated with huge financial cost and

engineering expense. An economical alternative to the conventional sensor-based ProcessMonitoring is the data-based ProcessMonitoring

of the existing signals from the machine control using MachineLearning algorithms. Dive into the current topics of DataScience

and IoT as a new member of the research circle grinding technology AKS and participate in the development of the data-based

ProcessMonitoring systems of tomorrow in collaboration with the WZL and multiple leading companies in grinding technology.

More informations:

Christian Wrobel, M. Sc

+49 (0) 241 80 27372

C.Wrobel@wzl.rwth-aachen.de

Why don’t you take a look at our research projects. For example conducted WZL a project funded by DFG to create a model

predicting the grinding wheel wear dependent on the cemented carbide specification. Earlier projects already proved that

the grinding of cemented carbides is highly dependent on the cemented carbide specification. This research suggests that

in addition to influencing the machining behavior of the workpiece material, the specification also influences the wear

behavior of the grinding tool. Single grain scratching experiments and grinding experiments, in combination with the

analysis of the workpiece and the grinding tool, are the foundation for the model. These and other questions concerning

tool production are also being researched in the Industrial Research Circle Tooling Technology (AKWT).

More informations:

Alexander Dehmer M. Sc

+49 (0) 241 80 24981

A.Dehmer@wzl.rwth-aachen.de

Centerless grinding is considered to be the supreme discipline of grinding processes. A larger number of process setting variables compared

to external cylindrical grinding between centers makes process design and optimization very complex. A new concept of process monitoring for

centerless grinding is currently researched by the Chair of Industrial Metrology at the Leipzig University of Applied Sciences and the WZL.

The researchers from Leipzig have developed a method for oscillation diagnosis in centerless grinding machines using laser-optical sensors.

The suitability of this measurement for predicting the workpiece quality is investigated in cooperation with the grinding experts at the WZL.

More informations:

Jannik Röttger M. Sc

+49 (0) 241 80 24959

J.Roettger@wzl.rwth-aachen.de

A large part of the energy introduced during grinding is converted into heat. Since the cooling lubricant can not dissipate all the heat, thermally induced displacements

in machine components occur, which have a negative influence on the component quality. To avoid component defects due to thermal displacement of machine components,

numerical-analytical methods are developed at the #WZL as a part of the transregional collaborative research center SFB TR96. These methods allow a prediction of the

thermo-mechanical load on the workpiece during the grinding process as a function of the grinding wheel topography. Thus enabling compensation for thermally inducted displacements.

More informations:

Marc Bredthauer M. Sc

+49 (0) 241 80 25416

M.Bredthauer@wzl.rwth-aachen.de

In the cutting tool industry, machining of superhard materials like polycrystalline diamond and

polycrystalline cubic boron nitride has always been a challenge. Despite the rise of laser processing

as promising manufacturing technology, grinding is still widely used in the industry. This is mainly

due to the high surface quality and due to the small heat-affected zone. In order to lower the grinding

wheel wear and the processing time and thus boost the productivity of grinding superhard materials, we

are constantly working on new grinding strategies, grinding tools, and process monitoring solutions in

our lab at wzl.

More informations:

Ulrich Müller M. Sc

+49 (0) 241 80 28188

U.Mueller@wzl.rwth-aachen.de

Many companies face the challenge of finding a suitable post-processing solution for their additively manufactured components to meet the tolerances after

the heat treatment. In order to provide even better support as an independent partner, WZL has expanded its post-processing research field by three additional machines.

The machines, which base on Abrasive Flow Machining (AFM), Robot-guided Centrifugal Finishing (RCF) and Vibratory Finishing (VF), are used in particular for the

post-processing of additive manufactured components in cooperation with DAP. Futhermore, they are suitable for any application where components with complex geometry

are manufactured with high demands on surface roughness.

More informations:

Marius Ohlert M. Sc

+49 (0) 241 80 27429

M.Ohlert@wzl.rwth-aachen.de

In aerospace, the #automotiveindustry as well as the energy and medicaltechnology, thin-walled components are increasingly required and designed

due to current trends such as resourceefficiency and lightweightconstruction. When grinding thin-walled components, adapted grinding and spark-out strategies

are needed for grinding. The relationships between the component wall thickness, the process parameters and the component deformation as a function of the grinding

and spark-out strategies for grinding thin-walled components are systematically researched at WZL.

More informations:

Sebastian Prinz M. Sc

+49 (0) 241 80 20393

S.Prinz@wzl.rwth-aachen.de

Turbinenschaufeln aus hochwarmfesten High-Tech-Werkstoffen müssen im Flugzeugtriebwerk höchsten thermischen und mechanischen Belastungen standhalten. Die hohe Härte und

Zähigkeit dieser Werkstoffe erschweren die Zerspanung.

Optimierte Schleifstrategien für die wirtschaftliche Bearbeitung hochwarmfester Werkstoffe werden derzeit im Arbeitskreis Schleiftechnik AKS entwickelt. Dazu wird

u. a. der Einfluss der CBN-Kornspezifikation auf die Schleifscheibenstandzeit bei der Bearbeitung von MAR M 247 untersucht. Basierend auf den Untersuchungsergebnissen werden

Handlungsempfehlungen zur Produktivitätssteigerung in der industriellen Praxis abgeleitet.

Der AKS ist ein Forschungsnetzwerk mit aktuell 26 Mitgliedsfirmen. Gemeinsam werden zukünftige Trendthemen produzierender Unternehmen identifiziert und relevante Fragestellungen

für die Schleiftechnik abgeleitet, die in Forschungsprojekten am Werkzeugmaschinenlabor WZL beantwortet werden. Unternehmen werden befähigt, aktuelle Forschungsergebnisse

effizient und frühzeitig im eigenen Betrieb umzusetzen.

Weitere Informationen:

Jannik Röttger M. Sc

+49 (0) 241 80 24959

J.Roettger@wzl.rwth-aachen.de